Přejít k obsahu | Přejít k hlavnímu menu | Přejít k vyhledávání

Moving forward and leaving quality results is what matters to the people at ELKO EP. Time passes and with time comes new challenges, challenges are closely connected with innovation and innovation is necessary, because whoever does not innovate is as if they do not exist.

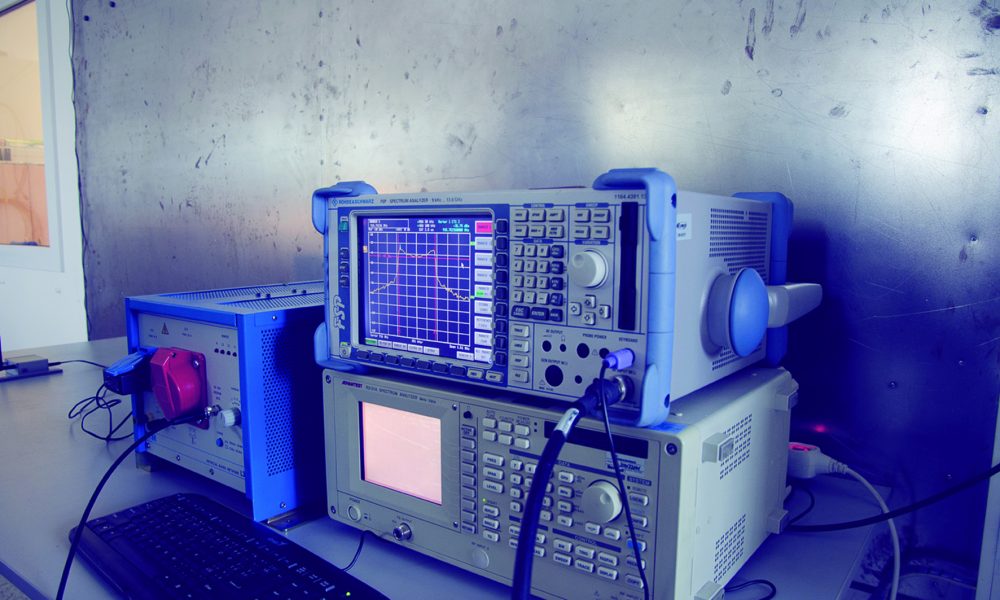

The ELKO EP company has been on the market for a quarter of a century, producing electrical modular devices including wireless elements, devices for electrical installations, and deals with proposals for complex solutions in the field of automation. All products are manufactured in such a way as to ensure maximum quality. ELKO EP describe the products with a laser and mark each product with a QR code that simply leads to the installation manual, emphasize a quality working environment, work with lead-free soldering technology, and all relays comply with the RoHS directive, which deals with the reduction of harmful substances in electrical equipment. ELKO EP has their own accredited laboratory, and it will be today’s topic that we will discuss in detail. The laboratory corresponds to the ISO 17025:2018 standard, it is led by Pavel Prekop, and we asked him to specify more closely what such work looks like.

Pavel, what is your job, what does the work in the laboratory actually entail and what is the result?

The result of our work is now an extensive test report in the English language, which contains an average of around 60 pages and serves as a basis for issuing the EN and CZ versions of the declaration of conformity. Since 2005, when the very first protocol, which was not even close to today’s standard, saw the light of day, our laboratory has already published several thousand protocols and gained considerable experience in the field.

But how is such a test report actually created and what does it cover?

Each of our devices must be safe and must withstand electromagnetic (EM) interference that comes from the environment and is generated by the operation of other devices. At the same time, the product must not be a source of EM interference above the acceptable limit set by the standards. And that is exactly what we are trying to achieve through various, often over-the-limit tests according to the relevant Czech, European and international standards. The progress and results of these tests are subsequently recorded in detail in this test report.

How many of you currently work in the laboratory?

There are currently 2 of us here. In the photo, my colleague David (the one in the middle) got into the shot.

Is there anything else that your laboratory deals with?

There is quite a lot, just randomly – creating plans, managing the system, legislative support and technical support for our company and its branches, testing replacement parts, specific tests for customers, tests of competing products, measuring radio characteristics, etc.

You have recently successfully completed the accreditation process, is that true?

Yes, it’s true, our laboratory is newly accredited according to ČSN EN ISO/IEC 17025:2018. I think it is one of the milestones of the ELKO EP, s.r.o. laboratory.

I heard that you are able to offer services to external customers as well, so what kind of services are these?

These are primarily EMC tests according to a wide range of standards, which are the subject of the already mentioned accreditation, but also safety tests, climate tests, measurement of various non-electric quantities and the like. Recently, the interest of externs has been growing. The interested parties are from manufacturers of automation systems, control systems, devices for transport technology, electric drives, PCBs for the space industry, various modules, etc.

Thanks for the interview Pavel.